when to use metal junction box Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic Junction Box: Plastic . I use a 4 1/8 hole saw for both cut in plastic and metal octagonal and fan boxes. A 4 inch leaves a little trimming to be done with the plastic boxes where the tabs are, no problem with sheetrock, just push it in, a little tougher with lath and plaster.

0 · why are junction boxes used

1 · where are junction boxes located

2 · utility box vs junction

3 · residential junction box

4 · junction box wiring guidelines

5 · junction box vs distribution

6 · junction box and utility difference

7 · different types of junction box

Below are the top 9 Best Welders for Metal Sheets and everything you need to know about them: 1. YESWELDER TIG-205DS HF TIG/Stick/Arc TIG Welder, 205 Amp 110 & 220V Dual Voltage TIG Welding Machine with Foot Pedal. YESWELDER.

why are junction boxes used

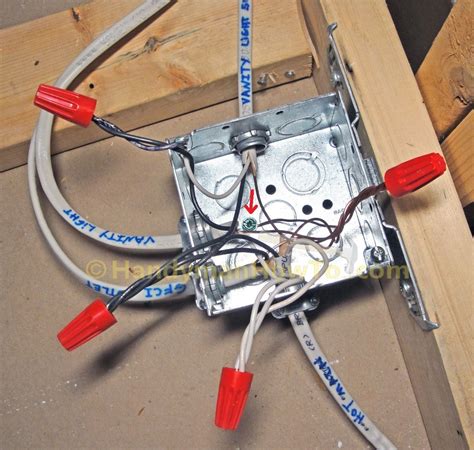

Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit runs in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box to complete grounding. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). You’ll also need to install cable clamps in the metal box. These thread into the box from the outside.

where are junction boxes located

Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic Junction Box: Plastic .

Metal boxes are required in some situations and have some unique benefits. They provide better heat dissipation, durability, and fire resistance. These boxes also include built-in clamps for metal-clad cables and .

This guide will help you understand what is a junction box is and get the best possible junction box for yourself without any struggle when you need one. Follow the instructions, and you’ll soon find a reliable junction box!

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .

Although these junction boxes are a convenient place to protect the wiring system, they will require the appropriate cover to help keep everything in working order. Suppose you are a home or property owner searching for the . Metal junction boxes offer durability and grounding capabilities, making them suitable for outdoor and industrial applications. Plastic junction boxes are lightweight and .

Metal Junction Boxes. Metal junction boxes are one of the most common types of electrical boxes used in residential and commercial installations. These boxes are typically made of steel or aluminum and offer excellent durability and protection. They are often used in areas where there is a higher risk of physical damage or exposure to moisture .

utility box vs junction

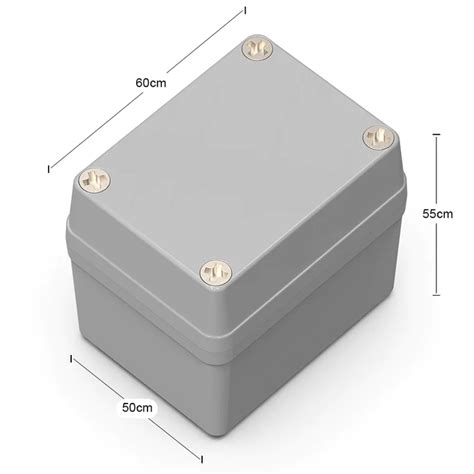

When it comes to electrical installations, the choice between a metal or plastic junction box depends on the unique requirements of your project. Plastic boxes are cost-effective and lightweight. They are widely used for .Electrical Junction Box, Steel Indoor&Outdoor Electrical Enclosure Box, Charging Station Box Wall Mounted &Dustproof Metal Box, Wall mouted Lock Box (12 * 10 * 6inch). 4.3 out of 5 stars 39Metal boxes are compatible with metal clad wires. Metal boxes have better shallow options and can easily be combined to make multigang options not available in plastic. Plastic boxes are cheaper and faster to work with but not so much so that it's worth an extra trip to a supply house. Commercial work there is no choice. We use metal boxes. Metal boxes are usually made of aluminum, steel or cast iron. The boxes made without metal are PVC or plastic. Metal Boxes: Many local building codes require metal junction boxes because they are durable and ensure long-lasting performance. Choose from many junction box sizes to find the one that best suits your project.

Metal vs. Plastic Junction Boxes When it comes to junction boxes, the debate often boils down to two materials: metal and plastic. Each has its pros and cons, so let’s break it down! Metal Junction Boxes Pros: Durability: Metal boxes . This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be machine threaded and green in color. Attach the ground wire to a metal junction box by wrapping the ground conductor around the screw the same direction the screw tightens. This is only necessary when using a metal junction box. Step 3: Attach the Grounding Wire to the Metal Junction Box. If you are using screws, insert the screw into the pre-drilled hole in the junction box and tighten it until snug. Then, attach the grounding wire to the screw. If you are using clamps, attach the clamp to the junction box and attach the grounding wire to the clamp.

So, should I use a metal or plastic junction box for under the insulation? If I use metal, I can ensure it is grounded via the splice. Thanks, Charlie . Upvote #2 10-25-18, 05:12 PM PJmax. Group Moderator. Join Date: Oct 2012. Location: Jersey. Posts: 67,136 Upvotes: 501 Received 4,386 .

You can't use a voltmeter to check the box by putting one of your probes to one side of the box and one on the other side. You need to kill all power to the electrical circuits in the box and using you continuity tester to "ring out" which hot wire is going to ground at the box.

314 says in order to use it as a junction box that contains splices the body has to be stamped with the amount of cubic area, but that doesn't exclude making holes in the side and adding additional raceways. . If it's listed as a junction box and it's made of metal, according to the NEC it has to have a tapped hole or equivalent for the . There are various types of junction boxes, including metal and plastic variants, each serving specific purposes in different applications. . Overcrowding the junction box, using the wrong type or size of the box, poor wire connections, .All My Favorite DIY Electrical Tools - https://www.amazon.com/shop/everydayhomerepairs Do you feel comfortable using metal electrical boxes on your DIY elect. Note the threaded entrance and locknut in the bottom right, along with the lack of any ground wires in the box -- that's a dead giveaway that this was done in metal conduit. Since the box is grounded through the conduit (which is as good a ground conductor as any), you don't even have to terminate the ground wire to the box as long as the Z .

Plastic is cheaper and probably more easier to work with (don’t need to ground the box), but it flexes more - if it’s for myself I’d probably use the metal and make sure it gets solidly mounted so that it doesn’t flex when you insert/unplug cables - but also like others have said, use single or double gang boxes, not these octagon boxesUnless you're using armored (BX, or metal-sheathed) wire, you can use either type box, your preference really. If you use BX, you need to use a metal junction box. There's a couple different types of boxes. The plastic ones with nails on .

Metal boxes should be used: When metal-sheathed cable or metal conduit is running in or out of the box. For interior exposed application such as in an unfinished basement or mudroom where there's no drywall. You can use a . There is generally no need for or point to having a watertight seal, if you are using the standard openings on a weatherproof box. The inside of the conduit is defined as (and normally meets the definition) a wet location. The back box will need to be chased into the walls at both points and as such they must be metal back boxes as the plastic back boxes are for surface mounting only. I can use the plastic back boxes inside the chase so that it’s flush when plastered, however there may be little gaps around the edges as the plastic back boxes are slightly .Per NEC standard 250.110, all metal junction boxes must be grounded. Our boxes have an embossed hole in the bottom of the box and grounding screw for the ground wire. Typically, our customers use metal shielded electrical cable or metal conduit with metal boxes. If the conduit is grounded, then a ground wire is not necessary as the connection .

cnc leather cutting machine price in india

just use a metal box that has the side mount bracket on it (like a RACO 235) and mount it so it ends up almost flush with joist bottoms. re run the lines thru the new holes you drill and staple to the sides nearest the entry to the box, then leave some extra and feed into the metal box. make sure to ground metal box when using romex

Correct. In a metal box, the ground wires from the cables go to the box's grounding screw first. Then, the switches pick up ground via their mounting screws, and receps pick it up either through a "self-grounding" feature against the screw threads, or via hard flush metal yoke-box contact, or via a ground pigtail to the screw or a clip.When metal junction boxes are grounded they must be properly bonded to the power source, such as to metal piping near the box, to a nearby metal ground rod, or to an appropriate grounding conductor inside the panel box. If metal junction boxes are not properly grounded, they may cause serious risks, such as electric shock or electrocution.

The only concern might be the plastic cover plate where edge protrudes beyond the box edge can be caught on and ripped off or broken, switching to a metal cover would be appropriate. And given aesthetics are not an issue internal of the cabinet metal cover should not be objectionable from an appearance perspective.

residential junction box

Find Weatherproof junction boxes at Lowe's today. Shop junction boxes and a variety of electrical products online at Lowes.com. Metal Junction Box: Durability: Metal junction boxes are generally more durable and resistant to impact compared to plastic boxes. They provide better protection in harsher environments or locations where the box may be subject to physical damage.

junction box wiring guidelines

We use a small 4x4 PVC box on the metal roof and will seal the top and side edges with M1, while putting a small bead on the bottom of the box. We have also worked with roofers on new roof installs and they have a certain type of sealant designed for metal roofs.

junction box vs distribution

Let’s take a look at the top five foundations for metal buildings, ranked from best to worst. 1. Concrete Slab Foundation — The Best Choice. Overview The concrete slab foundation is widely considered the best option for metal buildings. It involves pouring a thick, flat layer of concrete that serves as both the floor and the base for the .

when to use metal junction box|utility box vs junction